- Description

- Curriculum

📘 Description (Overview)

Learn how to implement and manage Pipeline Integrity Management Systems (PIMS), including inspection, corrosion control, risk assessment, and maintenance optimization—crucial for pipeline operations from design through decommissioning.

✅ What You Will Learn

-

Understand elements of PIMS, from policy to performance monitoring

-

Assess pipeline risks and apply direct assessment, ECDA, ICDA techniques

-

Plan inspections and integrity assessments (e.g., API, inline inspection)

-

Design corrosion control, repair strategies, and emergency readiness

-

Keep pipelines operational across lifecycle stages

🎯 Target Audience

Pipeline engineers, inspection specialists, technical maintenance leads, integrity officers, and project managers.

💬 Course Requirements

-

Engineering background (process/mechanical/pipeline)

-

Familiarity with pipeline systems; no prior integrity program experience required

🧩 Suggested Curriculum

-

PIMS Overview: Lifecycle & Regulatory Standards

-

Threat Identification & Risk Assessment (qualitative/quantitative)

-

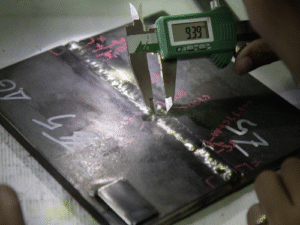

Inspection & Inline Tools: ILI, hydrotesting, ECDA, ICDA

-

Corrosion Control & Repair Strategies

-

Integrity Planning, Auditing, and Lifecycle Management

🎓 Outcome

Participants will confidently design and implement pipeline integrity programs, ensuring operational safety, regulatory compliance, and system reliability